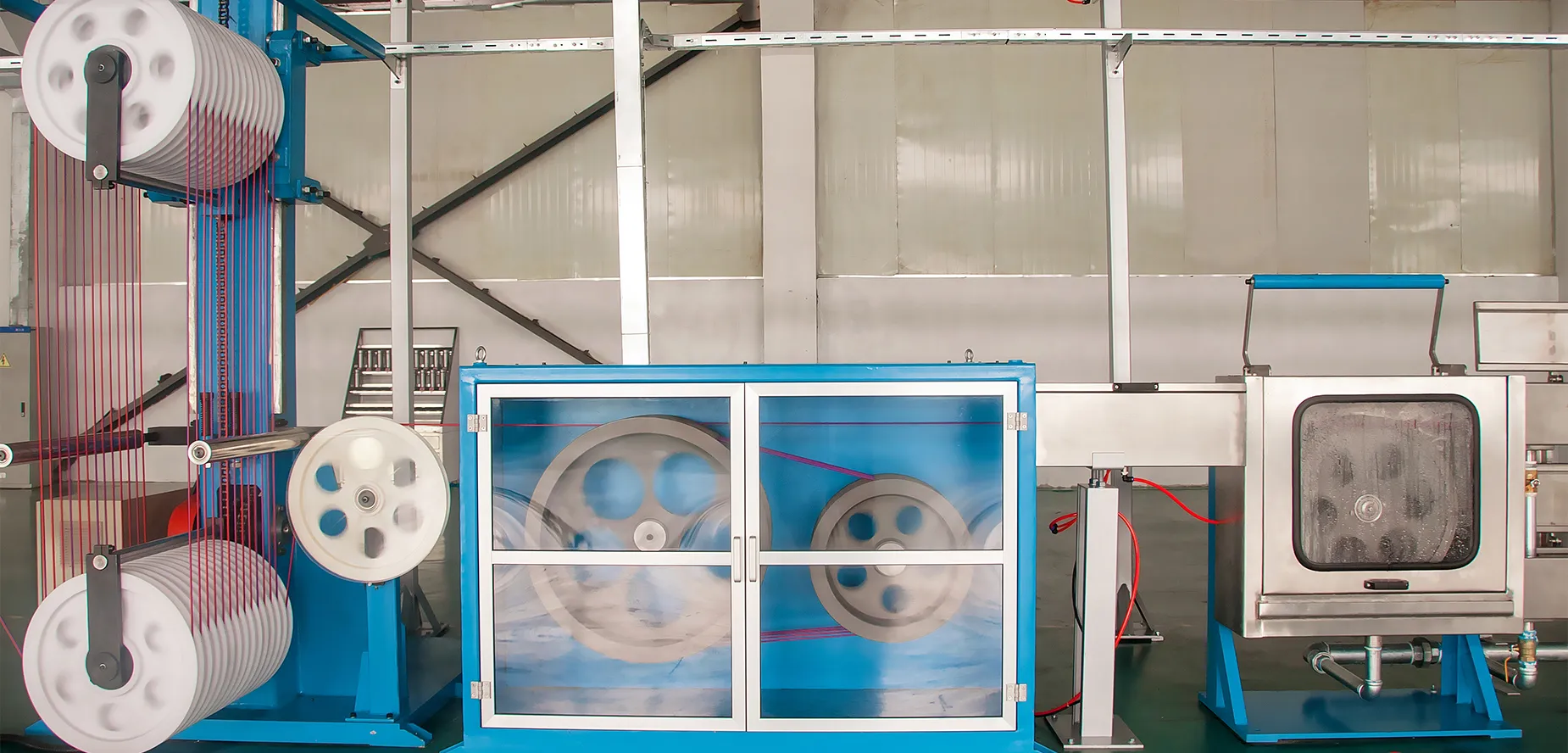

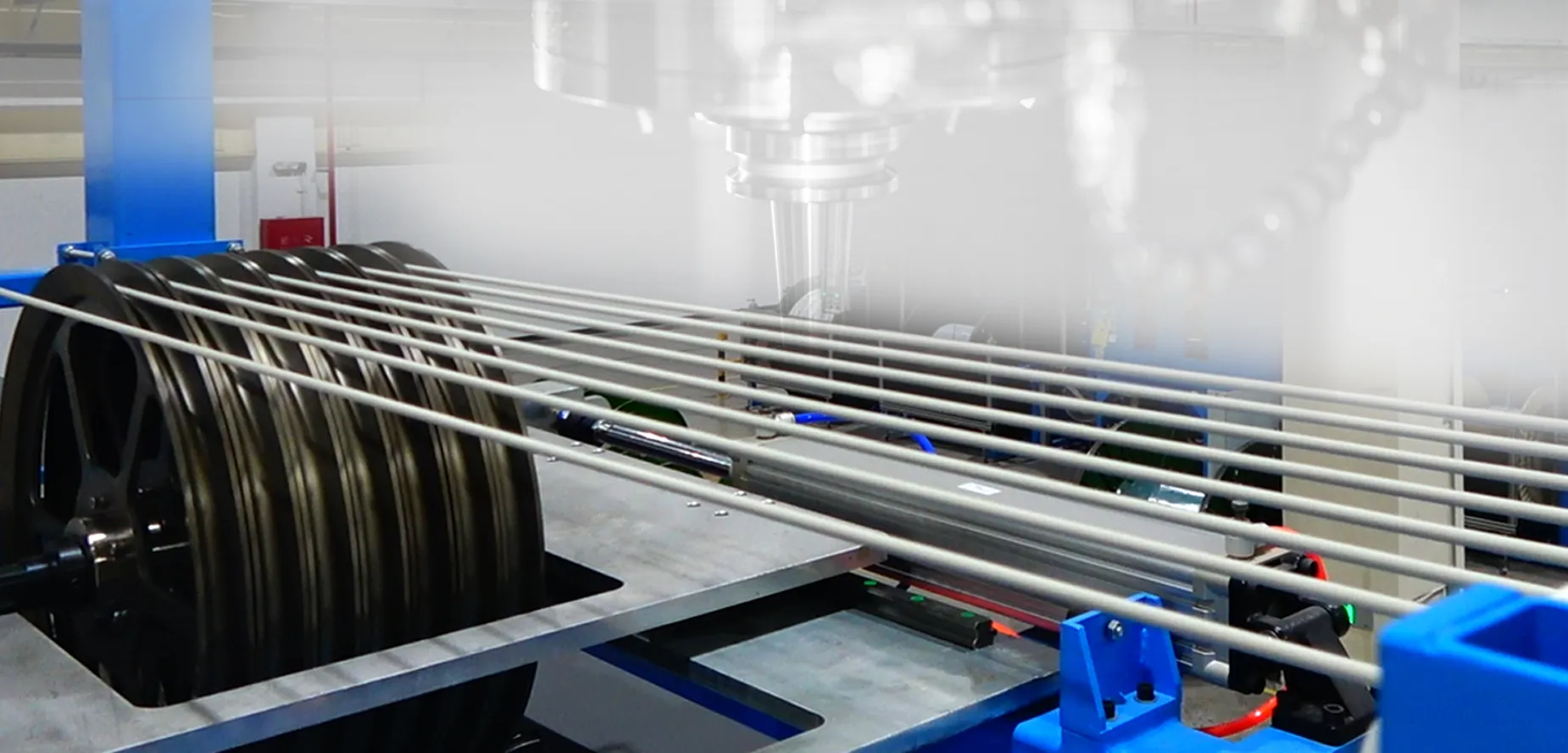

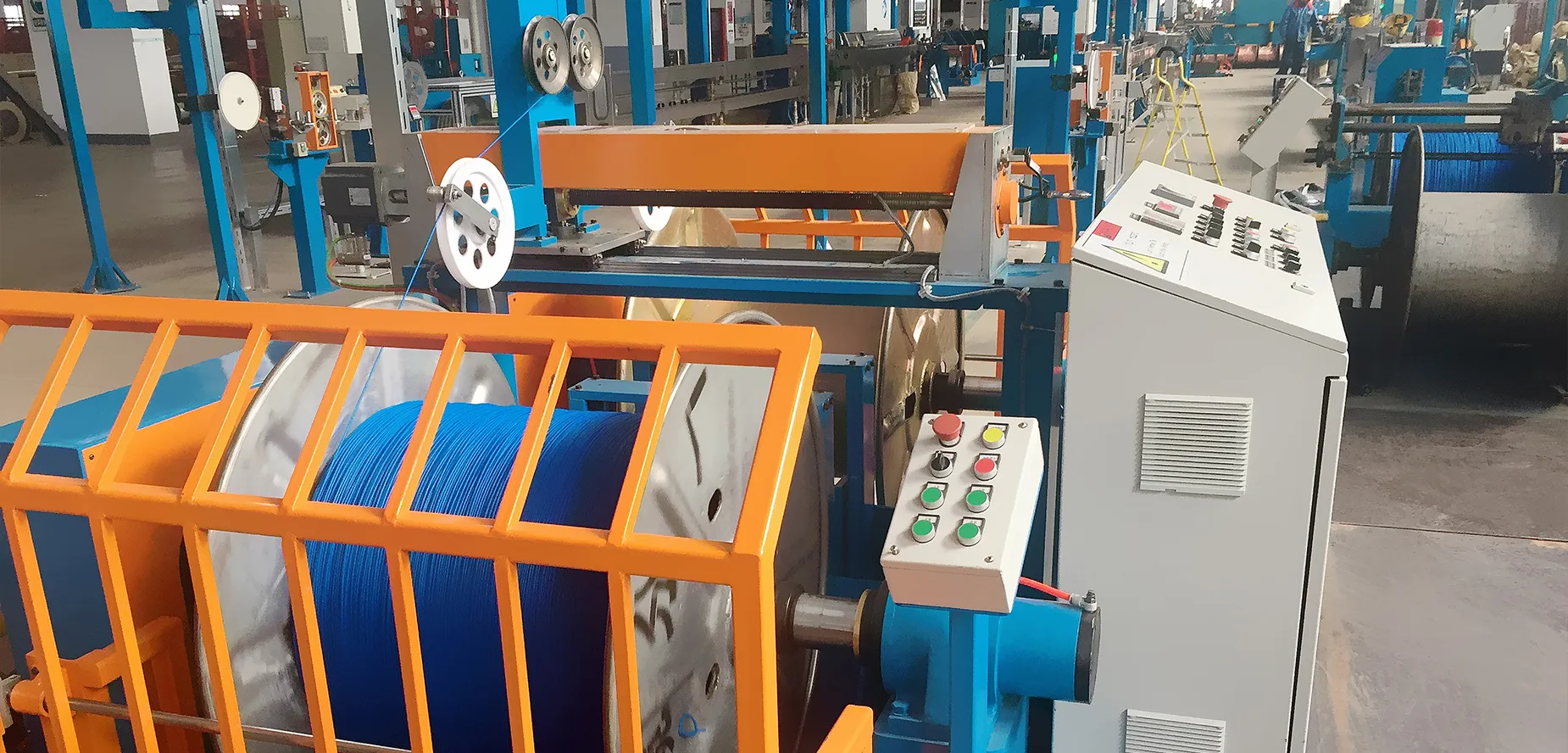

Cable accumulators act as buffer systems in cable manufacturing, balancing speed differences between upstream and downstream processes—such as extrusion, stranding, and winding—to maintain continuous production. Their primary function is to temporarily store cable materials, preventing line stoppages caused by reel changes, joint handling, or process downtime. At the same time, they stabilize material tension to prevent stretching, deformation, or breakage, making them essential auxiliary equipment for ensuring production efficiency and consistent product quality.