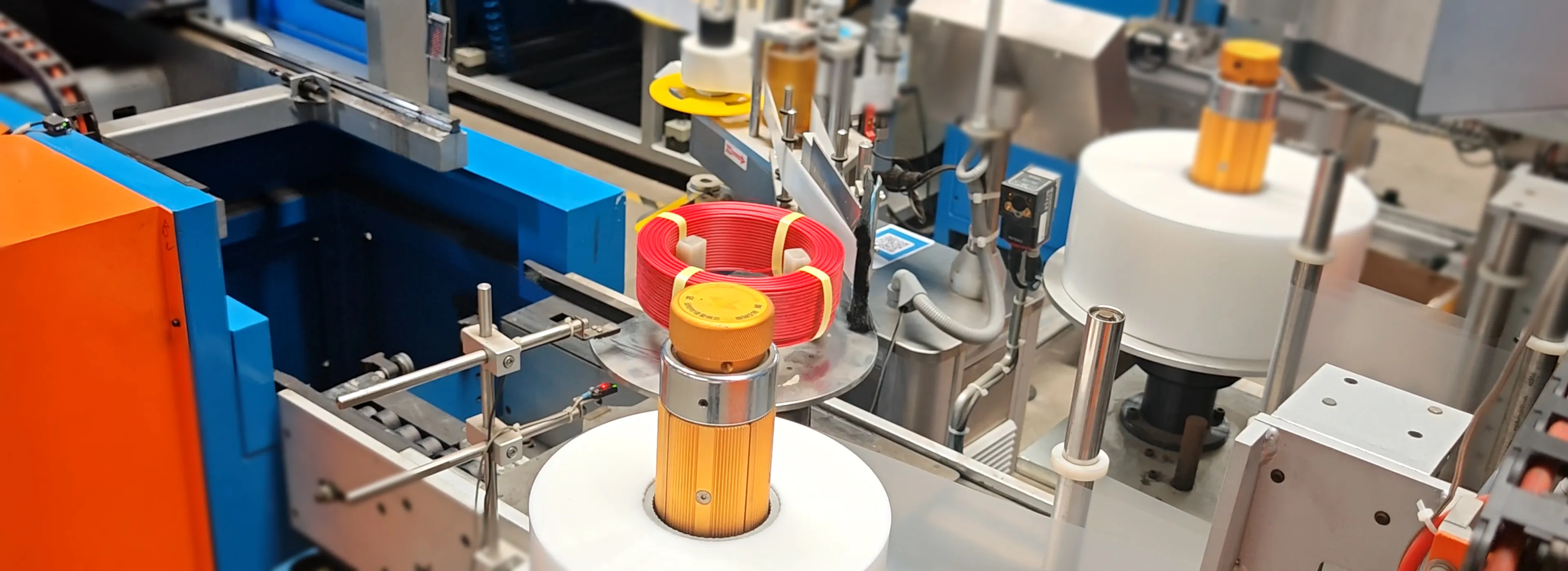

Intelligent extrusion solution for nylon sheath

Intelligent packaging solutions enhance packaging efficiency, reduce resource waste, and optimize logistics management by integrating IoT, artificial intelligence, automated control, and big data analytics. Through smart identification, automated packaging, eco-friendly materials, and personalized design, these solutions meet demands for efficiency, environmental sustainability, and user customization. Simultaneously, leveraging intelligent analysis and real-time monitoring technologies, they optimize production processes, inventory management, and transportation safety—delivering innovative solutions that lower costs, elevate brand value, and enhance customer experience for enterprises.