2024.12.04

2024.12.04

Cable equipment

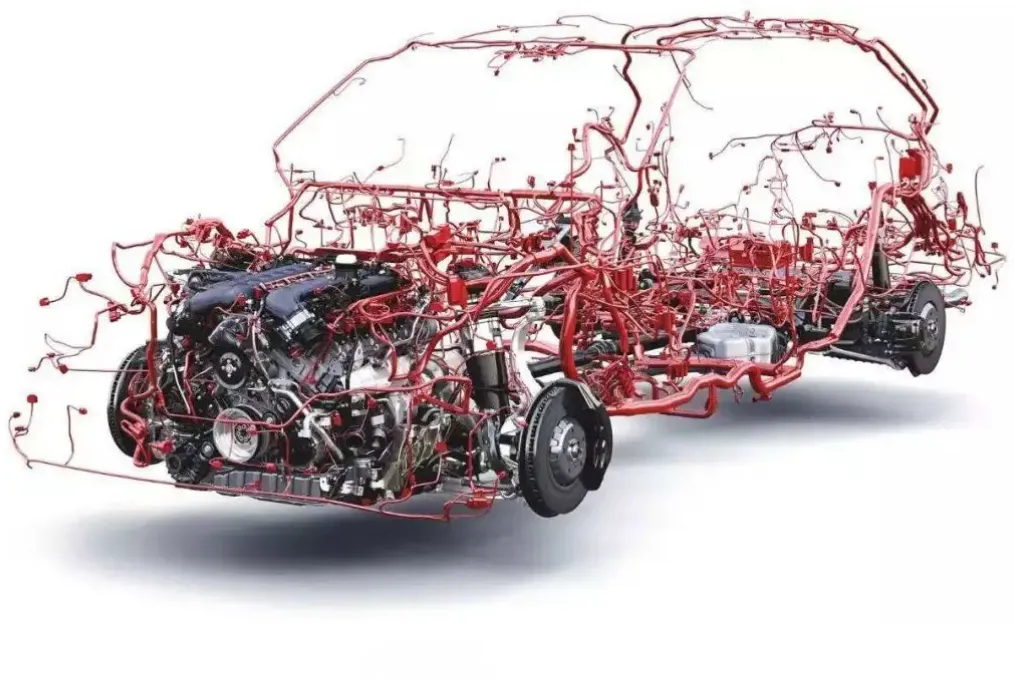

In this era of rapid technological advancement, connectivity and intelligence have become inevitable trends in the automotive industry. Future smart vehicles will transcend mere transportation tools, evolving into mobile hubs that seamlessly integrate life and work. As this automotive revolution deepens, data cables—the core components for in-vehicle information transmission—are undergoing unprecedented technological innovation. Functioning like a nervous system, they tightly interconnect major critical components, supporting the complex interactions and operations of smart vehicles.

Experts predict the global automotive data cable market will maintain steady growth in the coming years. On one hand, the burgeoning development of new energy vehicles is driving increasing demand for data cables. Their requirements for high-speed, high-stability data transmission open vast development opportunities for the market. On the other hand, the intelligent upgrades of traditional fuel-powered vehicles are expanding the application scope of automotive data cables, further fueling market growth. It is foreseeable that in the near future, to meet the growing demands for high transmission speeds and stability, the data cable market will provide a solid foundation for innovative development in the automotive industry. Data cables are no longer insignificant accessories but the “neural network” underpinning the core operations of smart vehicles.

As intelligence levels advance, data cables must deliver faster transmission speeds and enhanced stability to ensure real-time intelligent decision-making. In smart vehicles, environmental data and operational metrics collected by sensors require instant transmission to onboard computers, guaranteeing efficient execution of every operation. This places exceptionally high demands on data cable performance—only high-speed, stable data transfer can support the real-time transmission of massive data volumes, providing robust backing for intelligent decision-making.

Smart vehicles also require frequent interaction with the external environment, demanding robust interference resistance from data cables. Whether facing electromagnetic interference from electronic devices or signal disruptions in complex road conditions, data cables must maintain stable performance. Leveraging innovative designs, next-generation data cables achieve highly reliable data transmission across diverse challenging environments, safeguarding the performance of smart vehicles in complex scenarios.

As a steadfast partner to cable manufacturers, SINGCHEER Intelligent Manufacturing leverages advanced production capabilities and stringent quality standards to deliver comprehensive excellence in the development and production of automotive data cables. This includes coaxial cables (RF), low-voltage differential signaling (LVDS) cables, EtherNET cables, FlexRay cables, Controller Area Network (CAN) cables, and High-Speed Data (HSD) cables.

SINGCHEER Intelligent Manufacturing deeply integrates diverse data cable processes with varied customer requirements, meticulously crafting multiple extrusion production lines including physical foaming, chemical foaming, and solid-core insulation. These lines combine high speed, efficiency, energy savings, stability, and intelligence, delivering exceptional quality. With production speeds reaching up to 1000 meters per minute, they rank among the world's most advanced. The production line accommodates extrusion processes for multiple materials and features balanced tension control technology from pay-off to take-up. This ensures high consistency in product diameter, with fluctuations controlled within ±0.01mm and concentricity exceeding 95%. Insulation foaming is uniform and controllable, with capacitance deviation precisely maintained within ±1PF/m. The SINGCHEER Intelligent Manufacturing data cable sheath extrusion line delivers online longitudinal wrapping that is compact, flat, and uniform. Operating at speeds up to 200 meters per minute, its coordinated tension controllers for payoff and take-up, combined with low-tension traction spray tanks, achieve near-zero stretch on the cable core. The sheath concentricity exceeds 98%. SINGCHEER Intelligent Manufacturing exemplifies exceptional craftsmanship and extraordinary quality.